Product Description

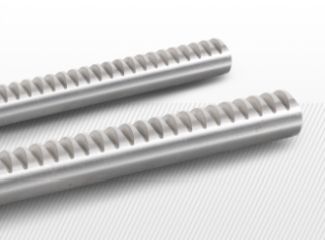

Custom High Precision CNC Machining Steel Gear Rack

| Specification LxWxH(mm) | Material | Module |

| 1005x8x30 |

A3 STEEL C45 STEEL Stainless Steel |

M4 |

| 1005x9x30 | M4 | |

| 1005x10x30 | M4 | |

| 1005x11x30 | M4 | |

| 1005x12x30 | M4 | |

| 1002x12x30 | M4 | |

| 1004x12x30 | M4 | |

| 1005x15x30 | M4 | |

| 1005x20x20 | M4 | |

| 1005x22x22 | M4 | |

| 1005x25x25 | M4 | |

| 1005x30x30 | M4 | |

| 1004x8x40 | M4 | |

| 1998x8x30 | M4 |

Use:

Mainly used in the mining, metallurgical, cement, chemicals,construction, buiding materials,

electric power, telecommunictions, textiles, and transportation departments.

Such as:

1. conveyor:Belt conveyor,AFC conveyor, chain conveyor, screw conveyor.

2. Pum:Water pump, oil pump, slush pump, etc.

3. Fan: Draft fan, fanner, boil fan, etc.

4. Excator:bucket excavator bucket, wheel excavators .

5. Crane:Tower crane, gantry crande, bridge crane.

6. Others:Various elevators, coal plough, ball mill, crusher, recreation machine.

7. Blender equipment, centrifuger, washer, leather-making machine, machine for recreation park mixer wire drawing machine.Extruder, dregs crusher of boiler.

8. Plastic feeder, rubber smelling machine, etc.

Main Products:

1. Timing Belt Pulley (Synchronous Pulley), Timing Bar, Clamping Plate;

2. Forging, Casting, Stampling Part;

3. V Belt Pulley and Taper Lock Bush; Sprocket, Idler and Plate Wheel;Spur Gear, Bevel Gear, Rack;

4. Shaft Locking Device: could be alternative for Ringfeder, Sati, Chiaravalli, Tollok, etc.;

5. Shaft Coupling:including Miniature couplings, Curved tooth coupling, Chain coupling, HRC coupling, Normex coupling, Type coupling, GE Coupling, torque limiter, Universal Joint;

6. Shaft Collars: including Setscrew Type, Single Split and Double Splits;

7. Gear & Rack: Spur gear/rack, bevel gear, helical gear/rack

8. Other customized Machining Parts according to drawings (OEM).

More Advantages:

1. More competitive prices,

2. Shorter delivery date: 35 days.

3. We are the professional manufacturer in the field of Power Trans. Parts,specially for Timing Pulleys.

4. Produce standard and non-standard

5. Strict QC Management:ISO9001:2008,our engineer,Mr.Wang has specialized in the prodcution for over 20 years.

Packaging & Shipping:

All the products can be packed in cartons,or,you can choose the pallet packing.

MADE IN CHINA can be pressed on wooden cases.Land,air,sea transportation are available.UPS,DHL,TNT,

FedEx and EMS are all supported.

Company:

ZheJiang MIGHTY MACHINERY Co.Ltd., a subsidiary company of ZheJiang Machinery Imp.&Exp. Corp(SCMIEC),which is a wholly stated-owned enterprise established in1980,specialized in producing precision mechanical power transmission products. After years of hard work,Mighty become the holding company of 3 manufacturing factories and also the 1 of the largest enterprise supply power transmission parts in western China.

Mighty’s products are mainly exported to Europe,America and Middle East market. With the top-ranking management,professional technical support and abundant export experience,Mighty has established lasting and stable business partnership with many world famous companies and has got good reputation from world wide customers in international sales.

Factory View:

Exhibition:

FAQ:

1. MOQ

A: Generally, 1 pc for standard parts; contact for nonstandard parts.

2. Delivery Time

A: In stock: within 5 working days. Out of stock: depends on your order quantity.

3. How To Select

A: part number or drawing, catalogue. If no, you can send us your sample, so we can make the drawing and sample accordingly.

4: What is the Warranty for your products?

A:Normally our warranty is 1 year.

| Standard or Nonstandard: | Standard & Custom |

|---|---|

| Feature: | Oil-Resistant, Corrosion-Resistant, Heat-Resistant, High Temperature-Resistance, etc. |

| Application: | Textile Machinery, Conveyer Equipment, Agricultural Machinery, and So on |

| Surface Treatment: | Blacking/Zinc/Electrophoresis/ Hardening Teeth etc |

| Material: | Steel/Plastic/42CrMo |

| Size: | Standard and Custom |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What types of materials are commonly used for round gear rack components?

Various materials are commonly used for manufacturing round gear rack components. Here’s a detailed explanation of the commonly used materials:

- Steel: Steel is one of the most widely used materials for round gear rack components. It offers excellent strength, durability, and resistance to wear. Steel gear racks are capable of handling high loads and provide reliable performance in demanding applications. Different grades of steel, such as carbon steel or alloy steel, can be used based on the specific requirements of the gear rack.

- Stainless Steel: Stainless steel is another popular material choice for gear rack components, especially in applications that require corrosion resistance. Stainless steel offers excellent resistance to rust, chemicals, and harsh environments. It is commonly used in industries such as food processing, pharmaceuticals, and marine applications where cleanliness, hygiene, and resistance to corrosion are critical.

- Plastic/Nylon: Plastic or nylon gear racks are preferred in certain applications due to their low friction, lightweight, and self-lubricating properties. They are commonly used in applications where noise reduction, smooth operation, and low maintenance are important considerations. Plastic gear racks also offer good resistance to chemicals and can be more cost-effective compared to metal alternatives.

- Brass: Brass is sometimes used for gear rack components, particularly in applications where low friction, good wear resistance, and corrosion resistance are required. Brass gear racks are commonly found in precision instruments, clocks, and small machinery.

- Cast Iron: Cast iron gear racks are known for their high strength, durability, and ability to dampen vibrations. They are commonly used in heavy-duty applications that require robust and rigid gear rack components. Cast iron gear racks are also suitable for applications with high temperatures and harsh operating conditions.

- Aluminum: Aluminum gear rack components are lightweight and offer good corrosion resistance. They are often used in applications where weight reduction is important, such as aerospace and automotive industries. However, aluminum has lower strength compared to steel or cast iron, so it is typically used in applications with lighter loads.

The choice of material for round gear rack components depends on factors such as load requirements, operating conditions, desired performance characteristics, and cost considerations. Each material has its own advantages and limitations, and the selection should be based on the specific needs of the gear rack application.

How do round gear racks contribute to efficient power transmission?

Round gear racks play a crucial role in enabling efficient power transmission in mechanical systems. Here’s a detailed explanation of how round gear racks contribute to efficient power transmission:

1. Force Distribution: Round gear racks distribute the transmitted power over a larger contact area compared to other types of power transmission mechanisms. The teeth of the gear rack engage with the mating gear or pinion, creating a line contact. This line contact allows for a larger surface area of contact between the gear teeth, resulting in improved force distribution and reduced stress concentration. By evenly distributing the transmitted force, round gear racks help minimize wear and prevent premature failure of the gear system components.

2. High Efficiency: Round gear racks offer high efficiency in power transmission. The teeth of the gear rack and the mating gear or pinion are designed to mesh with minimal backlash or clearance, resulting in efficient transfer of power. The precise tooth engagement reduces energy loss due to slippage or inefficient power transfer. Additionally, the use of high-quality materials and proper lubrication further enhances the efficiency of the gear rack system by reducing friction and minimizing energy losses.

3. Accurate and Repeatable Motion: Round gear racks provide accurate and repeatable motion, which is essential for efficient power transmission. The teeth on the gear rack are precisely spaced and designed to mesh with the mating gear or pinion, ensuring consistent and reliable motion transfer. This accuracy and repeatability contribute to the overall efficiency of the system by minimizing errors, misalignment, and vibrations that can lead to energy losses and reduced power transmission efficiency.

4. Load Handling Capability: Round gear racks are capable of handling high loads, making them suitable for power transmission in various applications. The design and material selection of the gear rack ensure it can withstand the forces and torque requirements of the system. By effectively distributing and transmitting the applied loads, round gear racks facilitate efficient power transmission without compromising the structural integrity of the gear system.

5. Versatility and Adaptability: Round gear racks offer versatility and adaptability in power transmission applications. They can be integrated into different types of gear systems, such as spur gears, helical gears, or bevel gears, depending on the specific requirements of the application. The ability to combine round gear racks with various mating gears or pinions allows for the customization of gear ratios, torque amplification or reduction, and the optimization of power transmission efficiency for different operating conditions.

Efficient power transmission is crucial in mechanical systems to minimize energy losses, maximize system performance, and ensure reliable operation. Round gear racks, with their force distribution characteristics, high efficiency, accurate motion, load handling capability, and versatility, contribute significantly to achieving efficient power transmission in a wide range of applications.

What are the primary components and design features of a round gear rack?

A round gear rack consists of several primary components and design features that enable its functionality and integration into machinery. Here’s a detailed explanation:

- Circular Shape: The most distinctive design feature of a round gear rack is its circular shape. Unlike straight gear racks that have a linear configuration, round gear racks are curved along the circumference of a circle. This curvature allows them to mesh with mating gears or pinions and facilitates rotary motion or motion along a curved path.

- Teeth: Similar to straight gear racks, round gear racks have teeth that engage with the mating gear or pinion. The teeth are evenly spaced along the curved surface of the rack. They are designed to match the tooth profile of the mating gear, ensuring proper meshing and torque transfer. The number, shape, and size of the teeth may vary depending on the specific application and design requirements.

- Material: Round gear racks are typically made of high-quality materials such as steel. The choice of material depends on factors such as load requirements, durability, and environmental conditions. The material used for the gear rack should possess suitable strength, wear resistance, and fatigue resistance to withstand the forces and stresses involved in the application.

- Mounting Holes: Round gear racks often feature mounting holes or slots along their curved surface. These holes or slots allow for secure attachment to the machinery or structure where they will be installed. The mounting holes provide flexibility in the positioning and alignment of the gear rack, ensuring proper engagement with the mating gear and facilitating easy installation and maintenance.

- Surface Finish: The surface finish of a round gear rack is essential for smooth and efficient operation. The teeth and curved surface should have a high-quality finish to minimize friction, reduce wear, and ensure reliable meshing with the mating gear. Proper surface treatment techniques such as grinding or honing may be employed to achieve the required surface finish and dimensional accuracy.

- Compatibility: Round gear racks are designed to be compatible with mating gears or pinions. The gear tooth profile, such as involute, is carefully matched between the gear rack and the mating gear to ensure proper meshing and efficient power transmission. The design parameters, including the modulus, pressure angle, and helix angle, should be considered to achieve the desired compatibility and performance.

In summary, the primary components and design features of a round gear rack include its circular shape, teeth for engaging with the mating gear, choice of material, mounting holes for installation, surface finish for smooth operation, and compatibility with mating gears. These features collectively enable the round gear rack to facilitate rotary motion or motion along a curved path in machinery applications.

editor by CX 2023-09-25