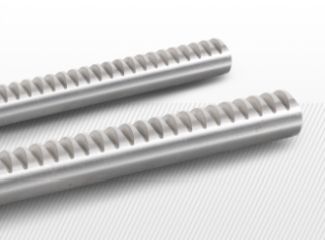

Product Description

We can supply the round gear rack ,Window Opener Gear Racks, Openning window gear racks, electric window opener gear racks, rack gears, racks, electric galvanized gear rack, steel gear rack, window gear rack, open window gear rack, window open gear rack, round gear rack, galvanized gear rack, white zinc galvanized gear rack, zinc galvanized gear rack, stainless steel gear rack, aluminium gear rack, aluminum gear rack, alumina gear rack, galvanizing gear rack, Sliding gate gear rack, Autogate gear rack, Nylon gear rack, Nylon Rack for sliding gate operator, plastic gear rack, CNC gear rack, Gear rack for sliding gate, Gear rack for window opener, Gear rack for openning window, Steel gear rack for cantilever sliding gate

We have been exporting durable and excellent quality rack and pinion including gear rack opening window, sliding door gear rack, engraving machine gear rack, industrial gear rack, curved gear rack and so on, we can produce as per your drawing or as per your sample. And we can also suggest gear rack as per your usage

Spur or helical gear rack and pinion/gears:

Module: M0.5-M30 It also available in DP

Length: Max. 7500mm

Max. Helical Angle: 30 Degree

Face Widths up to 300 mm

Material can be in Mild Steel, Alloy Steel, Hardened and Tempered Steels, Case carbonized/Case Hardened Steels, Cast Iron, or as specified material

We can produce as per your requested specifications, drawing or sample.

It is widely used in automotive and industrial field

Required information for quotation:

Material of rack and pinion

Module of teeth

Face Width

Height

Length

Fixing holes or thread holes if any

CONTACT US

| Length X Width X Height (MM) | |

| M1 15X15X1000 | |

| M1.5 17X17X1000 | |

| M2 20X20X1000 | |

| M2.5 25X25X1000 | |

| M3 30X30X1000 | |

| M4 40X40X1000 | |

| M5 50X50X1000 | |

| M6 60X60X1000 | |

| M8 80X80X1000 | |

| Length X Width X Height (MM) | |

| M1 15X15X1000 | |

| M1.5 17X17X1000 | |

| M2 20X20X1000 | |

| M2.5 25X25X1000 | |

| M3 30X30X1000 | |

| M4 40X40X1000 | |

| M5 50X50X1000 | |

| M6 60X60X1000 | |

| M8 80X80X1000 | |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | Oil-Resistant, Heat-Resistant, High Temperature-Resistance |

| Application: | Textile Machinery, Conveyer Equipment, Packaging Machinery, Food Machinery, Agricultural Machinery |

| Surface Treatment: | Zinc Plating |

| Material: | Alloy |

| Module: | 1-10 |

| Samples: |

US$ 60/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can round gear racks withstand variations in environmental conditions?

Round gear racks are designed to withstand variations in environmental conditions to a certain extent, but their ability to do so depends on factors such as the materials used, surface treatments, and proper maintenance. Here’s a detailed explanation:

1. Temperature: Round gear racks can generally withstand a range of temperatures, but extreme temperature variations can affect their performance. High temperatures can cause expansion, leading to changes in gear meshing, increased friction, and accelerated wear. On the other hand, extremely low temperatures can make materials more brittle, reducing their strength and increasing the risk of damage. It is important to consider the material properties and choose appropriate lubricants or coatings that can withstand the anticipated temperature range.

2. Humidity and Moisture: Exposure to high humidity or moisture can cause corrosion and rust, which can degrade the performance and lifespan of round gear racks. Proper material selection and surface treatments, such as coatings or platings, can help enhance the gear rack’s resistance to moisture. Regular maintenance, including cleaning and lubrication, is essential to prevent moisture-related issues and ensure optimal performance.

3. Dust and Contaminants: Round gear racks operating in dusty or contaminated environments may experience accelerated wear and reduced efficiency. Dust and contaminants can act as abrasive particles, causing increased friction and premature wear of the gear teeth. Regular cleaning and maintenance, along with appropriate sealing measures, can help minimize the impact of dust and contaminants on gear rack performance.

4. Chemical Exposure: Round gear racks may encounter various chemicals or corrosive substances depending on the application environment. Chemical exposure can lead to material degradation, loss of strength, or corrosion. Choosing materials with appropriate chemical resistance and applying protective coatings or seals can help mitigate the effects of chemical exposure.

5. Vibration and Shock: Round gear racks can experience vibrations and shocks during operation, especially in high-speed or heavy-duty applications. Excessive vibration or shock loads can lead to increased wear, misalignment, or even gear tooth failure. Proper design considerations, such as adequate support structures and vibration-damping mechanisms, can help minimize the impact of vibrations and shocks on gear rack performance.

While round gear racks are designed to withstand variations in environmental conditions, it is important to assess the specific operating environment and choose appropriate materials, surface treatments, and maintenance practices to ensure optimal performance and longevity. Regular inspections, lubrication, and maintenance according to manufacturer guidelines can help detect and address any issues arising from environmental conditions, ensuring the gear rack’s continued reliability and performance.

How do round gear racks contribute to efficient power transmission?

Round gear racks play a crucial role in enabling efficient power transmission in mechanical systems. Here’s a detailed explanation of how round gear racks contribute to efficient power transmission:

1. Force Distribution: Round gear racks distribute the transmitted power over a larger contact area compared to other types of power transmission mechanisms. The teeth of the gear rack engage with the mating gear or pinion, creating a line contact. This line contact allows for a larger surface area of contact between the gear teeth, resulting in improved force distribution and reduced stress concentration. By evenly distributing the transmitted force, round gear racks help minimize wear and prevent premature failure of the gear system components.

2. High Efficiency: Round gear racks offer high efficiency in power transmission. The teeth of the gear rack and the mating gear or pinion are designed to mesh with minimal backlash or clearance, resulting in efficient transfer of power. The precise tooth engagement reduces energy loss due to slippage or inefficient power transfer. Additionally, the use of high-quality materials and proper lubrication further enhances the efficiency of the gear rack system by reducing friction and minimizing energy losses.

3. Accurate and Repeatable Motion: Round gear racks provide accurate and repeatable motion, which is essential for efficient power transmission. The teeth on the gear rack are precisely spaced and designed to mesh with the mating gear or pinion, ensuring consistent and reliable motion transfer. This accuracy and repeatability contribute to the overall efficiency of the system by minimizing errors, misalignment, and vibrations that can lead to energy losses and reduced power transmission efficiency.

4. Load Handling Capability: Round gear racks are capable of handling high loads, making them suitable for power transmission in various applications. The design and material selection of the gear rack ensure it can withstand the forces and torque requirements of the system. By effectively distributing and transmitting the applied loads, round gear racks facilitate efficient power transmission without compromising the structural integrity of the gear system.

5. Versatility and Adaptability: Round gear racks offer versatility and adaptability in power transmission applications. They can be integrated into different types of gear systems, such as spur gears, helical gears, or bevel gears, depending on the specific requirements of the application. The ability to combine round gear racks with various mating gears or pinions allows for the customization of gear ratios, torque amplification or reduction, and the optimization of power transmission efficiency for different operating conditions.

Efficient power transmission is crucial in mechanical systems to minimize energy losses, maximize system performance, and ensure reliable operation. Round gear racks, with their force distribution characteristics, high efficiency, accurate motion, load handling capability, and versatility, contribute significantly to achieving efficient power transmission in a wide range of applications.

What advantages do round gear racks offer for precise linear motion?

Round gear racks offer several advantages for achieving precise linear motion in machinery and equipment. Here’s a detailed explanation of the advantages:

- Smooth Operation: Round gear racks provide smooth and uniform linear motion due to their curved shape. As the mating gear or pinion engages with the teeth along the curved rack, the motion is evenly distributed, resulting in consistent linear movement. This smooth operation is crucial for applications that require precise and controlled linear motion.

- Reduced Friction: The curvature of round gear racks reduces the contact area between the teeth of the rack and the mating gear or pinion. This results in lower friction compared to straight gear racks, leading to improved efficiency and reduced wear. The reduced friction allows for more accurate and repeatable linear motion, especially in applications that demand high precision.

- Increased Load Capacity: Round gear racks have a higher load-carrying capacity compared to their straight counterparts. The curved shape of the rack distributes the load over a larger contact area, enabling it to handle higher forces and loads. This increased load capacity is advantageous in applications where heavy loads need to be moved with precision along a linear path.

- Flexibility in Design: Round gear racks offer design flexibility due to their curved nature. Their curvature allows for versatile integration into machinery and equipment, especially when linear motion needs to follow a curved path. Round gear racks can be customized to match specific curvatures and radii, providing design engineers with greater flexibility in achieving precise linear motion in complex applications.

- Improved Stability: The curved shape of round gear racks enhances the stability of the linear motion system. The engagement between the rack and the mating gear or pinion is continuous along the curved surface, providing better support and preventing lateral movement or backlash. This improved stability ensures consistent and reliable linear motion, which is crucial for precision-based applications.

- Reduced Noise and Vibration: Round gear racks tend to generate less noise and vibration compared to straight gear racks. The curved engagement between the rack and the mating gear or pinion helps to minimize impact and noise during operation. This advantage is particularly beneficial in applications where quiet operation is desired or where excessive vibration can affect the accuracy and performance of the linear motion system.

These advantages make round gear racks a preferred choice for achieving precise linear motion in various machinery and equipment. Their smooth operation, reduced friction, increased load capacity, design flexibility, improved stability, and reduced noise and vibration contribute to the overall performance and accuracy of linear motion systems.

editor by CX 2024-04-04