Product Description

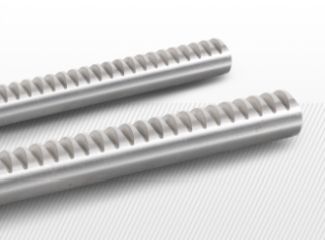

High precision DIN8 pinion gear cnc and round gear racks M0.5, M1,M2, M3, M4, M5,M6,M8

Product Description

Mighty can produce full series racks. M0.5/M1/M1.5/M2/M2.5/M3/M4/M5/M6/M7/M8

| Material | Aluminium6061/6063/7075/5052 etc |

| Stainless steel303/304/400/316,SteelQ235,20#,45#etc | |

|

Brass:C36000(C26800),C37700(HPb59),C38500(HPb58),C2200(CuZn37), C28000(CuZn40) etc, |

|

| Copper;Beryllium bronze copper. | |

| Process | CNC turning,CNC milling, CNC grinding;CNC lathe machining, CNC boring;CNC drilling, surface treatment |

| Surface treatment | Hardness anodizing black/clear, steel oxidizing dark-blue, electro-polishing, electroless nickel plating, silver plating, CHINAMFG plating etc |

| Tolerance | +/-0.001mm or +/- 0.00004″ |

| Certification | ISO9001:2008, ROHS |

| Production capacity | depend on complicacy of different products and the quantity |

| Experience | 15 years of CNC machining products |

| Packaging | standard export carton with pallet or as per customes’requirement |

| Lead time | making arrangement CHINAMFG customers’request |

| Term of Payment | T/T, L/C, Escrow, paypal, western union |

| Part size | Diameter from 0.5mm to 1000mm |

| Minimum Order | Comply with customer’s demand |

| Delivery way | EXPRESS, BY SEA OR BY AIR on your requirement. |

| Maine equipment | Machining center, CNC, Lathe, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine etc. |

| Testing facility | Coordinate measuring machine, projector, roughness tester, hardness tester, concentricity tester. Height tester, . |

| General Tolerance(+/-mm) | |

| Milling | 0.005 |

| Turning | 0.005 |

| Grinding(Flatness/in2) | 0.003 |

| ID/OD Grinding | 0.002 |

| Wire-Cutting | 0.002 |

Dimensions:

Product photo:

Other Types of RACKS:

PACKING

| Packaging | |

| Packing

|

We use standard export wooden case, carton and pallet, but we can also pack it as per your special requirements. |

OUR COMPANY

ZheJiang Mighty Machinery Co., Ltd. specializes in offering best service and the most competitive price for our customer.

After over 10 years’ hard work, MIGHTY’s business has grown rapidly and become an important partner for oversea clients in the industrial field and become a holding company for 3 manufacturing factories.

MIGHTY’s products have obtained reputation of domestic and oversea customers with taking advantage of technology, management, quality and very competitive price.

Your satisfaction is the biggest motivation for our work, choose us to get high quality products and best service.

OUR FACTORY

Main Products:

Timing belt pulleys, timing bars, timing belt clamping plates.

Locking elements and shrink discs: could be alternative for Ringfeder, Sati, Chiaravalli, BEA, KBK, Tollok, etc.

V belt pulleys and taper lock bush.

Sprockets, idler, and plate wheels.

Gears and racks: spur gear, helical gear, bevel gear, worm gear, gear rack.

Shaft couplings: miniature coupling, curved tooth coupling, chain coupling, HRC coupling, normex coupling, FCL coupling, GE coupling, rigid and flexible coupling, jaw coupling, disc coupling, multi-beam coupling, universal joint, torque limiter, shaft collars.

Forging, Casting, Stamping Parts.

Other customized power transmission products and Machining Parts (OEM).

Application

1. Engineering: machine tools, foundry equipments, conveyors, compressors, painting systems, etc.

2. Pharmaceuticals& Food Processing: pulp mill blowers, conveyor in warehouse, agitators, grain, boiler, bakery machine, labeling machine, robots, etc.

3. Agriculture Industries: cultivator, rice winnower tractor, harvester, rice planter, farm equipment, etc.

4. Texitile Mills: looms, spinning, wrappers, high-speed auto looms, processing machine, twister, carding machine, ruler calendar machine, high speed winder, etc.

5. Printing Machinery: newspaper press, rotary machine, screen printer machine, linotype machine offset printer, etc.

6. Paper Industries: chipper roll grinder, cut off saw, edgers, flotation cell and chips saws, etc.

7. Building Construction Machinery: buffers, elevator floor polisher mixing machine, vibrator, hoists, crusher, etc.

8. Office Equipments: typewriter, plotters, camera, money drive, money sorting machine, data storage equipment, etc.

9. Glass and Plastic Industries: conveyor, carton sealers, grinders, creeper paper manufacturing machine, lintec backing, etc.

10. Home Appliances: vacuum cleaner, laundry machine, icecream machine, sewing machine, kitchen equipments, etc.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contacts

We warmly welcome friends from domestic and abroad come to us for business negotiation and cooperation for mutual benefit. To supply customers excellent quality products with good price and punctual delivery time is our responsibility.

Any question or inquiry, pls contact us without hesitate, we assure any of your inquiry will get our prompt attention and reply!

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Toothed Portion Shape: | Spur Gear |

| Material: | C45 |

| Standard or Nonstandard: | Standard /Nonstandard |

| Certification: | ISO9001:2008 |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can round gear racks withstand variations in environmental conditions?

Round gear racks are designed to withstand variations in environmental conditions to a certain extent, but their ability to do so depends on factors such as the materials used, surface treatments, and proper maintenance. Here’s a detailed explanation:

1. Temperature: Round gear racks can generally withstand a range of temperatures, but extreme temperature variations can affect their performance. High temperatures can cause expansion, leading to changes in gear meshing, increased friction, and accelerated wear. On the other hand, extremely low temperatures can make materials more brittle, reducing their strength and increasing the risk of damage. It is important to consider the material properties and choose appropriate lubricants or coatings that can withstand the anticipated temperature range.

2. Humidity and Moisture: Exposure to high humidity or moisture can cause corrosion and rust, which can degrade the performance and lifespan of round gear racks. Proper material selection and surface treatments, such as coatings or platings, can help enhance the gear rack’s resistance to moisture. Regular maintenance, including cleaning and lubrication, is essential to prevent moisture-related issues and ensure optimal performance.

3. Dust and Contaminants: Round gear racks operating in dusty or contaminated environments may experience accelerated wear and reduced efficiency. Dust and contaminants can act as abrasive particles, causing increased friction and premature wear of the gear teeth. Regular cleaning and maintenance, along with appropriate sealing measures, can help minimize the impact of dust and contaminants on gear rack performance.

4. Chemical Exposure: Round gear racks may encounter various chemicals or corrosive substances depending on the application environment. Chemical exposure can lead to material degradation, loss of strength, or corrosion. Choosing materials with appropriate chemical resistance and applying protective coatings or seals can help mitigate the effects of chemical exposure.

5. Vibration and Shock: Round gear racks can experience vibrations and shocks during operation, especially in high-speed or heavy-duty applications. Excessive vibration or shock loads can lead to increased wear, misalignment, or even gear tooth failure. Proper design considerations, such as adequate support structures and vibration-damping mechanisms, can help minimize the impact of vibrations and shocks on gear rack performance.

While round gear racks are designed to withstand variations in environmental conditions, it is important to assess the specific operating environment and choose appropriate materials, surface treatments, and maintenance practices to ensure optimal performance and longevity. Regular inspections, lubrication, and maintenance according to manufacturer guidelines can help detect and address any issues arising from environmental conditions, ensuring the gear rack’s continued reliability and performance.

How do round gear racks contribute to efficient power transmission?

Round gear racks play a crucial role in enabling efficient power transmission in mechanical systems. Here’s a detailed explanation of how round gear racks contribute to efficient power transmission:

1. Force Distribution: Round gear racks distribute the transmitted power over a larger contact area compared to other types of power transmission mechanisms. The teeth of the gear rack engage with the mating gear or pinion, creating a line contact. This line contact allows for a larger surface area of contact between the gear teeth, resulting in improved force distribution and reduced stress concentration. By evenly distributing the transmitted force, round gear racks help minimize wear and prevent premature failure of the gear system components.

2. High Efficiency: Round gear racks offer high efficiency in power transmission. The teeth of the gear rack and the mating gear or pinion are designed to mesh with minimal backlash or clearance, resulting in efficient transfer of power. The precise tooth engagement reduces energy loss due to slippage or inefficient power transfer. Additionally, the use of high-quality materials and proper lubrication further enhances the efficiency of the gear rack system by reducing friction and minimizing energy losses.

3. Accurate and Repeatable Motion: Round gear racks provide accurate and repeatable motion, which is essential for efficient power transmission. The teeth on the gear rack are precisely spaced and designed to mesh with the mating gear or pinion, ensuring consistent and reliable motion transfer. This accuracy and repeatability contribute to the overall efficiency of the system by minimizing errors, misalignment, and vibrations that can lead to energy losses and reduced power transmission efficiency.

4. Load Handling Capability: Round gear racks are capable of handling high loads, making them suitable for power transmission in various applications. The design and material selection of the gear rack ensure it can withstand the forces and torque requirements of the system. By effectively distributing and transmitting the applied loads, round gear racks facilitate efficient power transmission without compromising the structural integrity of the gear system.

5. Versatility and Adaptability: Round gear racks offer versatility and adaptability in power transmission applications. They can be integrated into different types of gear systems, such as spur gears, helical gears, or bevel gears, depending on the specific requirements of the application. The ability to combine round gear racks with various mating gears or pinions allows for the customization of gear ratios, torque amplification or reduction, and the optimization of power transmission efficiency for different operating conditions.

Efficient power transmission is crucial in mechanical systems to minimize energy losses, maximize system performance, and ensure reliable operation. Round gear racks, with their force distribution characteristics, high efficiency, accurate motion, load handling capability, and versatility, contribute significantly to achieving efficient power transmission in a wide range of applications.

How do round gear racks handle variations in load capacity and speed?

Round gear racks are designed to handle variations in load capacity and speed in machinery and equipment. Here’s a detailed explanation of how they address these variations:

- Load Capacity: Round gear racks are capable of accommodating different load capacities based on their design and construction. The load capacity of a round gear rack depends on factors such as the material used, tooth profile, tooth size, and overall dimensions. Manufacturers specify the load capacity ratings for round gear racks, allowing engineers to select the appropriate rack that can handle the expected loads in their specific application. By choosing a round gear rack with the appropriate load capacity, variations in loads can be effectively managed.

- Speed: Round gear racks can handle variations in speed by considering factors such as tooth pitch and tooth engagement. The tooth pitch determines the linear displacement per revolution of the mating gear or pinion. By selecting a suitable tooth pitch, the desired linear speed can be achieved. Additionally, the number of teeth engaged at any given time affects the speed capability. Increasing the number of engaged teeth can distribute the load and reduce the strain on individual teeth, allowing for higher speeds. However, it’s important to consider the trade-off between speed and the load capacity of the gear rack. Higher speeds may require a more robust rack design to maintain stability and ensure reliable operation.

- Lubrication and Maintenance: Proper lubrication and maintenance play a crucial role in handling variations in load capacity and speed. Lubrication helps reduce friction and wear between the teeth of the gear rack and the mating gear or pinion, ensuring smooth operation and extending the lifespan of the components. Regular maintenance, including inspection and lubrication, allows for early detection of any issues that may affect load capacity or speed. By following recommended maintenance practices, variations in load and speed can be effectively managed, ensuring optimal performance and longevity of the round gear rack.

- System Design and Control: The overall system design and control also contribute to handling variations in load capacity and speed. Engineers consider factors such as gear ratios, motor selection, and control algorithms to optimize the performance of the gear rack system. By appropriately sizing and configuring the system components, variations in load and speed can be accommodated. Additionally, advanced control techniques such as feedback control and velocity profiling can be employed to regulate speed and manage load fluctuations, ensuring smooth and precise operation of the round gear rack system.

By considering factors such as load capacity, speed, lubrication, maintenance, system design, and control, round gear racks can effectively handle variations in load capacity and speed. Proper selection, maintenance, and system design practices help ensure reliable and efficient operation of machinery and equipment that incorporate round gear racks.

editor by CX 2023-12-28